Power Generation Filtration Solutions

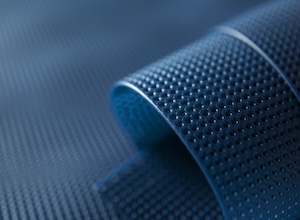

NxtNano excels in delivering filtration solutions tailored for gas turbine power generators, crucial in environments demanding uninterrupted operation. Our range of nTEX and nHIBIT filter media withstands varied and harsh conditions—ensuring your turbines perform optimally everywhere from scorching deserts to frigid arctics. Each product is rigorously tested to meet rigorous standards, ensuring your power generation systems receive the most reliable and effective filtration technology available.

Maximize Your Turbine’s Efficiency

Adaptable Efficiency

Achieves up to 99.99% filtration efficiency, protecting engine components from damaging dust particles.

Enhanced Durability

Designed for harsh environments, our media withstand extreme conditions, enhancing turbine longevity and reducing maintenance.

Optimal Performance

NxtNano’s filters support superior airflow and efficient dust cake removal, crucial for maintaining high turbine efficiency and extending filter life.

Explore how our filtration solutions can protect and optimize your power generation assets.

Why Choose NxtNano Filter Media for Power Generation?

Nanofiber technology is pivotal in reducing the total ownership cost of your engines, guided by three fundamental principles:

- Customized Solutions: We offer media options tailored to specific turbine environments—coastal, desert, arctic, and more—each designed to address unique challenges.

- Advanced Technology: Our nMAX gradient density nanofiber media deliver superior pulse response and extended service life—up to 70% longer than standard nanofiber media—making them ideal for demanding turbine environments.

- Technical Expertise: Beyond products, we provide full technical support, ensuring that each filter operates at its peak within your system.

-

Lower Total Cost of Ownership

Lower Total Cost of Ownership (TCO): The combination of unmatched filtration efficiency, enhanced airflow, and extended filter life drastically lowers the TCO compared to conventional filter media. This means less engine wear, fewer filter replacements, longer service intervals, and reduced costs related to downtime.

Applications of nTEX Nanofiber Filter Media

Coastal and Inland Applications

Ideal for gas turbines in coastal areas with hydrophobic HEPA options to withstand humidity and salt or inland installations requiring robust dust management.

Summary Chart

Description

Filtration Rating

Air Permeability (CFM)

Choose NxtNano for filtration that meets the high demands of power generation. Let’s enhance your operational efficiency and reduce downtime with our advanced filter media solutions.

NXTNANO DIFFERENCE

Technology & Capabilities

NxtNano powers next-generation performance with scalable nanofiber technology. Our HYPR Spinning™ platform delivers high-efficiency, fluorine-free materials tailored for filtration, textiles, membranes, and more. From concept to commercialization, we partner with innovators to engineer custom solutions that outperform and outlast. Ready to rethink what’s possible?

PARTNER WITH US

At NXTNano, we don’t just manufacture materials—we engineer performance. Our technology platform, testing capabilities, and collaborative approach are built to help you move faster, scale smarter, and innovate with confidence.