Technology + Innovation + Capabilities

Nanofiber Innovation at Scale

At the core of NxtNano’s platform is HYPR Spinning™—our proprietary nanofiber manufacturing technology designed for large-scale production without compromising quality. This process unlocks consistent, ultra-fine fiber deposition across wide formats with unmatched flexibility in performance tuning and polymer choice. From initial concept to final commercialization, we help bring your next-generation materials to life.

HYPR SPINNING™ TECHNOLOGY

High Performance, Precisely Tuned

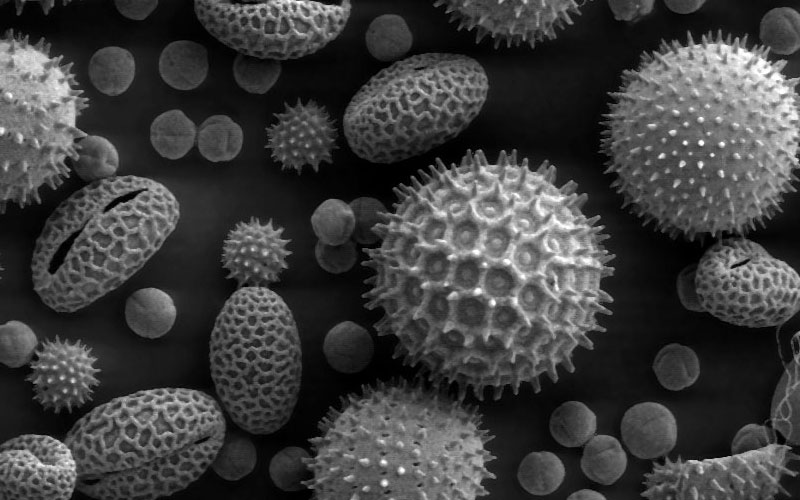

HYPR Spinning™ enables precise control over fiber diameter, pore structure, and basis weight, ranging from 0.1 to 15 GSM. Our nanofibers can be engineered with pore sizes from 0.1 micron to over 1 micron—ideal for applications requiring tailored filtration, breathability, or barrier properties.

Advantages Over Conventional Methods:

- Higher throughput + finer fiber size

- Consistent wide-format laydown

- Multi-polymer spinning capabilities

- Strong fiber-to-substrate adhesion without secondary lamination

PRODUCTION & PROCESSING CAPABILITIES

Whether you need ready-to-ship finished materials or integration-ready membranes, our production infrastructure is built for speed, scale, and customization.

- 5 HYPR Spinning™ Lines – 2.14-meter working width

- 2 Lamination Lines – Wide-format composite production

- 3 Slitting Lines – Precision conversion for roll goods

APPLICATIONS

From air filtration to apparel, our nanofiber media power critical functions across industries:

- Air Filtration: MERV 11 to HEPA H13

- Microporous Membranes: Waterproof, breathable barriers

- Life Sciences: Pharmaceutical and medical-grade media

- Technical Textiles: Protective wear and microfiltration layers

- Sustainable Materials: Biodegradable membrane options

Polymer Portfolio

We offer one of the broadest polymer ranges in the nanofiber industry. HYPR Spinning™ is compatible with:

| Polymer |

Example Applications |

| TPU (Thermoplastic Polyurethane) | Apparel membranes, pulse/static filtration |

|

PAN (Polyacrylonitrile) |

Specialty filtration, composites |

|

PES (Polyether Sulfone) |

Liquid membranes |

| PLA (Polylactic Acid) | Biodegradable and eco-conscious uses |

| P84 (Polyimide) | High-temperature filtration |

| Proteins | Biomedical, regenerative medicine |

| PEO (Polyethylene Oxide) | Cosmetics, wound healing |

LAB & TESTING CAPABILITIES

In-house testing is a critical part of our development process. We validate materials and filter media at every stage—from flat-sheet development to full-system performance.

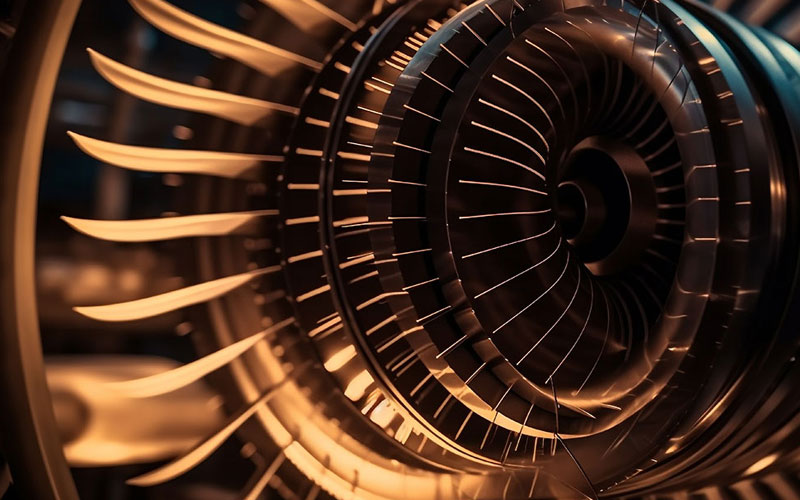

Filter Performance Testing

- Full Filter Duct: Dust loading, pressure drop, pulse response

- Configurations: Gas turbine, HVAC panels, mini-pleats

Media Efficiency Testing

- TOPAS Test Station: ASHRAE 52.2, EN1822, ISO 16890

- TSI 8130: Efficiency and penetration testing

Material Characterization

- SEM Imaging: Morphology analysis

- Bubble Point & Air Permeability

- Burst Strength & Gurley Stiffness

PARTNER WITH US

At NXTNano, we don’t just manufacture materials—we engineer performance. Our technology platform, testing capabilities, and collaborative approach are built to help you move faster, scale smarter, and innovate with confidence.